Samsung is reportedly about to launch a project to lower the production costs of Micro LED displays, in collaboration with its partners.

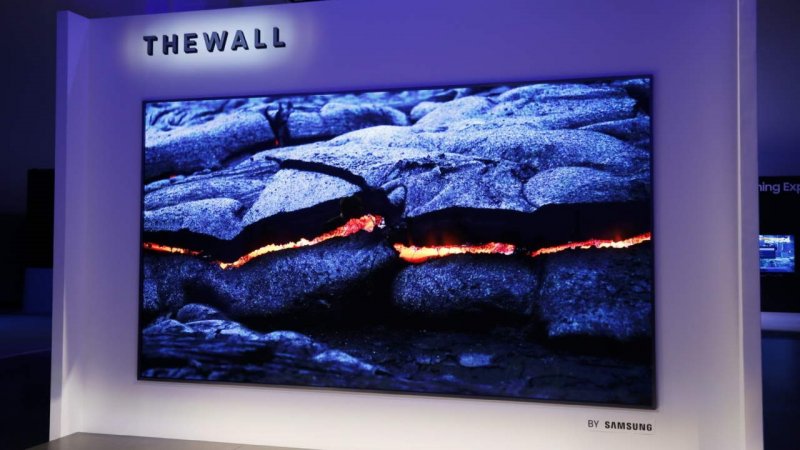

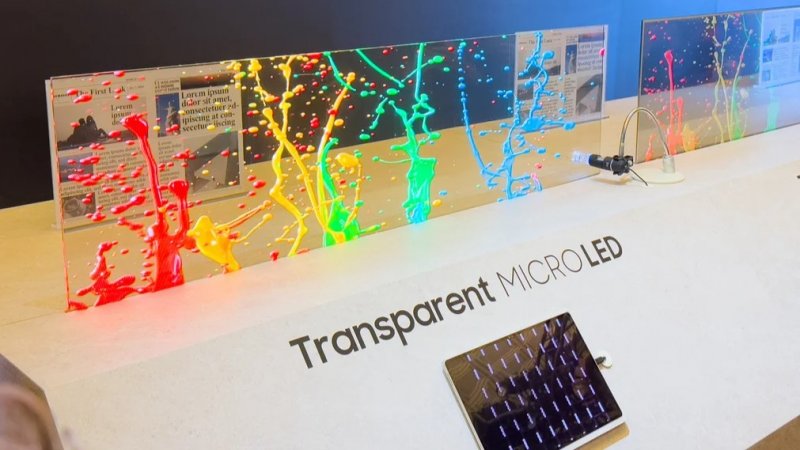

Samsung is among the most active manufacturers on the Micro LED front, a technology that for the Korean giant marks the next evolutionary step in the display segment. From the presentation of the first prototypes to today, the company has managed to greatly reduce the available diagonals, reaching the threshold of 75 inches.

However, production costs remain high, which inevitably affect the final price of the products: at the moment, in fact, about 1000 euros are needed for each diagonal of the screen, making it virtually prohibitive to land on the mass market. For this reason, Samsung would be willing to start a project, in collaboration with its partners, to reduce production costs in a rather short period of time. Let’s find out the details.

A 90% cut in 3 years

We recently showed you a 35-inch Micro LED display that gave us a first look at the future of TVs and monitors. In order to bring this technology into our homes, Samsung is said to be about to launch a project to reduce the production costs of Micro LED panels, with the aim of cut 90% of spending over the next 3 years.

The project also arises from the need to counter the advance of Chinese producers who are investing heavily in this segment.

Samsung has held several meetings with its main suppliers to identify weak points in the production chain and start an innovation process, putting a dedicated task force in charge of the project. The company has in fact achieved the development of the technologies necessary for the development of Micro LED panels and can therefore focus on reducing costs.

The challenges to face

A Micro LED panel requires millions of micron-sized LEDs to be produced on silicon wafers, which must then be transferred and soldered correctly onto the TFT substrate. The diodes must be selected to be extremely uniform in color, and a process must then be developed to identify and replace defective LEDs.

Finally, this type of panel is produced in modules, which must then be assembled with the utmost precision.

To create an efficient production system, the Korean government has invested approximately 320 million euros spread over 8 years, precisely to counter the Chinese advance. After losing the LCD challenge, Samsung does not want to lose ground on future technologies. As for us, we can’t wait to get our hands on Micro LED displays at an affordable price.

#Samsung #focuses #Micro #LED #project #reduce #production #costs #underway